-

Thin bed mortar is a mix of fine-ground sand, cement and other ingredients specific to Poroton construction. Mixed locally to laying, it allows for thin joints which will achieve full strength in just 24 hours. The Roller to apply the thin bed mortar allows for the swift and simple creation of true 1mm bed joints. The precision Collomix is a perfect, high standard solution for this job. Available sizes (width): 100mm, 240mm, 365mm, 425mm.

Thin bed mortar is a mix of fine-ground sand, cement and other ingredients specific to Poroton construction. Mixed locally to laying, it allows for thin joints which will achieve full strength in just 24 hours. The Roller to apply the thin bed mortar allows for the swift and simple creation of true 1mm bed joints. The precision Collomix is a perfect, high standard solution for this job. Available sizes (width): 100mm, 240mm, 365mm, 425mm. -

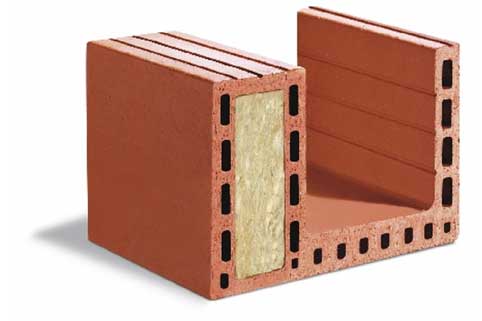

The U cups mainly used at the top of the wall to forming ring beam. The U cups with steel bars and concrete fill is a perfect solution at wall plate level. The formed ring beam, and the concrete gives you the freedom to fit any type of roof to your building. We also using the U blocks as a lintel above wider opening. The precast lintel available up to 2.5m (minus 2x150mm bearing) so above 2.3m wide opening we using these U blocks to forming a massive (insulated) lintel. Available sizes (width): 240mm, 300mm, 365mm, 425mm.

The U cups mainly used at the top of the wall to forming ring beam. The U cups with steel bars and concrete fill is a perfect solution at wall plate level. The formed ring beam, and the concrete gives you the freedom to fit any type of roof to your building. We also using the U blocks as a lintel above wider opening. The precast lintel available up to 2.5m (minus 2x150mm bearing) so above 2.3m wide opening we using these U blocks to forming a massive (insulated) lintel. Available sizes (width): 240mm, 300mm, 365mm, 425mm. -

The U cups mainly used at the top of the wall to forming ring beam. The U cups with steel bars and concrete fill is a perfect solution at wall plate level. The formed ring beam, and the concrete gives you the freedom to fit any type of roof to your building. We also using the U blocks as a lintel above wider opening. The precast lintel available up to 2.5m (minus 2x150mm bearing) so above 2.3m wide opening we using these U blocks to forming a massive (insulated) lintel. Available sizes (width): 240mm, 300mm, 365mm, 425mm.

The U cups mainly used at the top of the wall to forming ring beam. The U cups with steel bars and concrete fill is a perfect solution at wall plate level. The formed ring beam, and the concrete gives you the freedom to fit any type of roof to your building. We also using the U blocks as a lintel above wider opening. The precast lintel available up to 2.5m (minus 2x150mm bearing) so above 2.3m wide opening we using these U blocks to forming a massive (insulated) lintel. Available sizes (width): 240mm, 300mm, 365mm, 425mm. -

Used for mixing mortar locally, close to the block layer and team. It is a very similar process to mixing tile adhesive. The mortar will be supplied in a 15kg bag with the blocks. This is mixed with 9.6 litres of water and will effectively lay one full pack of blocks, eliminating the need for barrowing many mixes of sand/cement mortar. Faster and more efficient. There are many different brands of paddle mixer available. We can supply any tools necessary to complete the project.

Used for mixing mortar locally, close to the block layer and team. It is a very similar process to mixing tile adhesive. The mortar will be supplied in a 15kg bag with the blocks. This is mixed with 9.6 litres of water and will effectively lay one full pack of blocks, eliminating the need for barrowing many mixes of sand/cement mortar. Faster and more efficient. There are many different brands of paddle mixer available. We can supply any tools necessary to complete the project. -

U value 0.31W/m2K

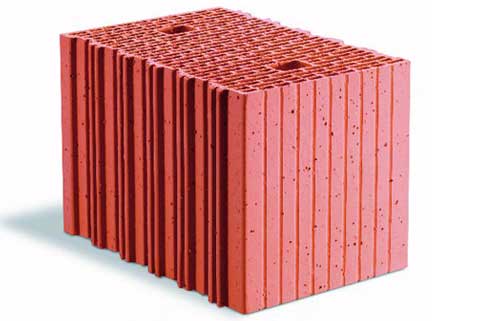

The Porotherm clay block system is a monolithic wall structure, so no cavity just solid wall. You will use these blocks for your external wall where is the thermal performance is important. Used from DPC (damp-proof course) up to roof plate level and also for gables. Available block sizes (wall thickness): 240mm, 300mm, 365mm, 425mm, 490mm. All block sizes available with or without integrated mineral wool insulation. -

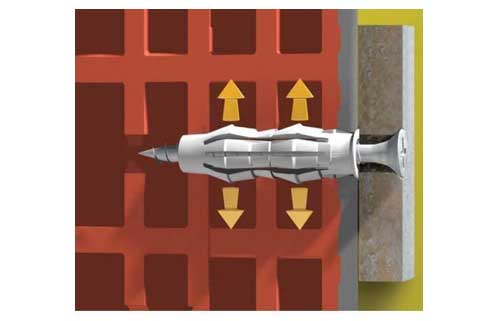

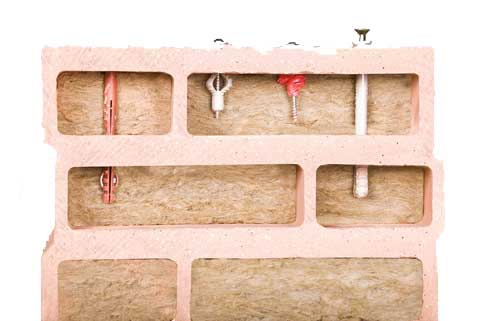

Fixing to the poroton blocks is easier like ever before. Use any drill bit you want without hammer function. You can use even a timber drill or hole saw…. A wide variety of fixtures and accessories are available for use with the Porotherm systems, some specifically created to work with this system alone (in conjunction with industry leading partners) and others available as standard items.

Fixing to the poroton blocks is easier like ever before. Use any drill bit you want without hammer function. You can use even a timber drill or hole saw…. A wide variety of fixtures and accessories are available for use with the Porotherm systems, some specifically created to work with this system alone (in conjunction with industry leading partners) and others available as standard items. -

20kg bag A rolled on parge coat is an alternative to wet plaster parge coats to provide an airtight barrier prior to the application of plasterboard on dabs for internal finishes. Eco-parge can be easily applied by brush or roller ensuring a fast, de-skilled application. Coverage: Approximately 20sqm per bag. Note: These estimates take no account of wastage

20kg bag A rolled on parge coat is an alternative to wet plaster parge coats to provide an airtight barrier prior to the application of plasterboard on dabs for internal finishes. Eco-parge can be easily applied by brush or roller ensuring a fast, de-skilled application. Coverage: Approximately 20sqm per bag. Note: These estimates take no account of wastage -

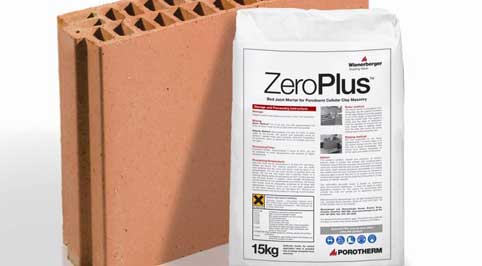

15KG Bag Porotherm ZeroPlus mortar is a thin-joint mortar for building with Porotherm from zero degrees - so you don't have to stop in cold weather, saving time and money!

15KG Bag Porotherm ZeroPlus mortar is a thin-joint mortar for building with Porotherm from zero degrees - so you don't have to stop in cold weather, saving time and money!Specifically formulated for Porotherm

The ZeroPlus™ thin-joint mortar is specially formulated for the Porotherm construction system, enabling it to be laid at zero degrees Celsius on a rising scale. ZeroPlus™ has been validated for use at 0oC by the UK testing house Lucideon. The innovative mixture has been designed to provide the same performance at between 0oC and 3oC as existing thin-joint and traditional mortar, which can only be used at temperatures of 3oC and above. -

The Porotherm Ceiling Panel DRS® is specially adapted to the Monolithic Porotherm product range as an end insulation at first floor level with concrete slab. It is the ideal system supplement for monolithic masonry in object and single-family house construction. The brick shell ensures an optimal plaster base as the material change in the grate area is eliminated. Standing walled, the Porotherm Ceiling Panel DRS® can also be used as front insulation when integrating the partition wall into the outer wall.

The Porotherm Ceiling Panel DRS® is specially adapted to the Monolithic Porotherm product range as an end insulation at first floor level with concrete slab. It is the ideal system supplement for monolithic masonry in object and single-family house construction. The brick shell ensures an optimal plaster base as the material change in the grate area is eliminated. Standing walled, the Porotherm Ceiling Panel DRS® can also be used as front insulation when integrating the partition wall into the outer wall.